Causes and Levels of Postharvest Losses along Amaranthus Supply Chain

*Corresponding Author(s):

Oluoch OBPwani University, School Of Agricultural Sciences And Agribusiness, Department Of Crop Sciences, Kilifi, Kenya

Email:bacaogalo@gmail.com

Abstract

Amaranthus spp., is one of the oldest and most widely grown vegetables in the tropical and sub-tropical regions of the world. Kenyan coast where amaranthus is grown for human consumption and income generation, the crop is faced with a myriad of challenges, hence affecting its production. Over 90% of the Kenyan coast is arid and semi-arid, with declining and unpredictable rainfall, poor soil fertility, pests and diseases being the major factors contributing to low crop yields. Despite dwindling production of amaranthus in the region due to disease, pests, salinity, high temperatures, high humidity, and limited moisture at critical stages of growth, the little harvested crop is still vulnerable to heavy qualitative and quantitative losses. There is limited information on the causes of losses and postharvest quality management of amaranthus in coastal Kenya. The objective of this study was to determine the causes of postharvest losses of amaranthus in Coastal Kenya. The study was carried out between August to November, 2022 in three counties namely Kilifi, Mombasa and Kwale counties. A purposive sampling procedure was used to randomly select farmers, transporters, consumers, retailers and supermarket attendants from each county of within the urban and peri-urban areas to respond to the questionnaire. Variables collected through the questionnaire were socio-demographic profiles causes of postharvest losses along the supply chain node, means of transport, storage, and packaging. Data collected from the three counties were pooled and examined for descriptive statistics. The means and percentages were used to describe results. From the study, causes of postharvest losses varied with supply chain. Major causes of postharvest losses reported were inappropriate harvest techniques, lack of proper storage conditions, improper handling of the produce, bad weather conditions, inappropriate storage conditions, lack of appropriate packaging, and mixed commodity storage. The most common means of transporting amaranthus was by use of tuk-tuk (32.3 to 40.2%) or motorcycle (28.4 to 37.8%). The most common type of storage of amaranthus was under room conditions or open air (63.8 to 89.4%). The most common packaging used was sacks and nets However, old newspaper were being used in the open markets. Polyethylene bags that have been banned in Kenya were secretly being used. Major qualitative losses of amaranthus observed were yellowing which was highest in the open-air markets (21 to 40%). Wilting was highest after transportation (41 to 60%). Foreign bodies were highest at harvest (21 to 40%). Mechanical damage was highest at harvest and during transportation (21 to 40%). Pest damage did not vary along the supply chain. The highest quantitative and economic loss was between 52.7 to 57.9% depending on the amaranthus supply chain. Improving harvesting techniques and handling practices, enhancing storage conditions, and promoting proper packaging methods tailored to each node of the chain. Additionally, investing in transportation infrastructure and cold storage systems can help minimize postharvest loss.

Keywords

Coastal; Food loss; Food quality; Food waste; Kenya; Shelf-life

Introduction

Amaranthus spp., is one of the oldest and most widely grown vegetables in the tropical and sub-tropical regions of the world [1]. This could be attributed to its adaptability to grow in a wide range of climatic conditions, tolerance to drought, salinity and requires minimum management for growth [2].

In Kenya, the vegetable is mainly grown in the coastal region both for consumption and income generation [3,4]. It is the most preferred in the region because it grows faster with minimal input. The vegetable is essential both for human and livestock nutrition. Amaranthus has high yield potential, nutritional value, and medicinal value. It is a source of dietary fibre, inexpensive protein, and its consumption helps in balancing the uptake of minerals and vitamins [2]. Cooked leaves are rich in vitamins A and C, Fe, Ca, protein (8%) and carbohydrates (4%). Apart from amaranthus being rich in minerals and vitamins, it is also vital in the intake for health promoting factors, because of its high content of phenolic compounds [5].

Kenyan coast where amaranthus is grown for human consumption and income generation, is faced with a myriad of challenges affecting production and quality of the crop. Over 90% of the Kenyan coast is arid and semi-arid, with declining and unpredictable rainfall, poor soil fertility, pests and diseases, high temperature and relative humidity, hence being the major factors contributing to low crop yields and poor quality [6]. Soil salinity in the region also affects the production of amaranthus since accumulated salts in the soil is known to negatively affect the physiological and metabolic process of the crop hence affecting its yield, growth and quality [7].

Despite dwindling production of amaranthus in the region, the little harvested crop is still vulnerable to heavy qualitative and quantitative postharvest losses [8]. This translates to loss of money and nutrients which contribute to an increase in food insecurity, malnutrition and poverty in the region.

Postharvest loss is known to be caused by postharvest handling and storage, genotype, harvest stage and environmental growing conditions. Harvest to consumption delays in vegetables may cause an indirect loss in quality of nutrients, flavour and direct loss due to decay, respiration and water loss [9].

Kenyan coast is characterised by high temperature, light and high humidity which adversely affect quality and shelf life of fresh vegetables [10]. Physiological deterioration, microbial decay and quality nutritional loss is attributed to water loss, microorganism contamination, and temperature injury which depend on temperature. Loss of water from warm products is greatly influenced by windy conditions for example during transportation in an open vehicle [11]. Higher temperature increases the rate of respiration and transpiration of vegetables resulting in shorter postharvest shelf life [12].

In Kenya, there is a significant postharvest loss of indigenous vegetables of up to 50%, which varies with the vegetable species [13]. There is limited information on the causes of losses and postharvest quality management of amaranthus in coastal Kenya. The objective of this study was to evaluate postharvest losses and its causes along amaranthus supply chain in coastal Kenya.

Methodology

Description of the Study Area

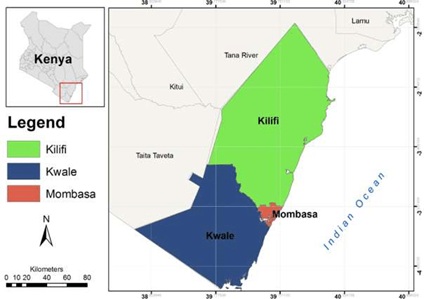

The study was carried out between August to November, 2022 in three counties namely Kilifi, Mombasa and Kwale counties (Figure 1). Kilifi county has a total population of 1,577,335, of which 783,992 are males, 793,343 are females. The area covers 12,540km2 with a population density of 125.8/km2. Located at an elevation of 5.09 meters above sea level. The area yearly temperature is 27.28ºC, 4.78% higher than Kenya’s averages. Kilifi typically receives about 102.11mm of precipitation and has 187.0 rainy days (51.23% of the time) annually (Table 1).

Mombasa county has a total population of 1,311,860, of which 653,546 are males, 658,314 are females. The area covers 219.9km2 with a population density of 5,966/km2. Located at an elevation of 22.74 meters above sea level. The city’s yearly temperature is 27.63 ºC, 5.13% higher than Kenya’s averages. Mombasa typically receives about 63.81mm of precipitation and has 151.1 rainy days (41.4% of the time) annually (Table 1).

Kwale county has a total population of 944,464, of which 468,412 are males, 476,052 are females. The area covers 8,267km2 with a population density of 114.2/km2. Located at an elevation of 382.14 m above sea level. The city’s yearly temperature is 27.63ºC, 5.13% higher than Kenya’s averages. Kwale typically receives about 63.81 mm of precipitation and has 151.1 rainy days (41.4% of the time) annually (Table 1).

Figure 1: Map of the study sites.

Figure 1: Map of the study sites.

|

Area (km2) |

Population by Gender |

Population by Age |

Total Population |

Population Density (no./km2) |

Weather Conditions |

|||||

|

Male |

Female |

0-14 |

15-64 |

<65 |

Altitude (m a.s.l) |

Annual Temperature (ºC) |

Annual Precipitation (mm) |

|||

|

A. Kilifi County |

||||||||||

|

12,540.0 |

783,992 |

793,343 |

546,330 |

940,143 |

90,862 |

1,577,335 |

125.8 |

5.09 |

27.28 |

102.11 |

|

B. Mombasa County |

||||||||||

|

219.9 |

653,546 |

658,314 |

436,252 |

846,188 |

29,420 |

1,311,860 |

5,966.0 |

22.74 |

27.63 |

63.81 |

|

C. Kwale County |

||||||||||

|

8,267.0 |

468,412 |

476,052 |

397,889 |

512,109 |

34,466 |

944,464 |

114.2 |

382.14 |

27.63 |

151.10 |

Table 1: Characteristics of the study site.

Note: Source: https://www.citypopulation.de/en/kenya/admin/coast

Sampling Procedure

A purposive sampling procedure was used to randomly select farmers, transporters, consumers, retailers and supermarket attendants from each county of within the urban and peri-urban areas to respond to the questionnaire due to their limited number and unstructured nature. The study areas were selected due to their intensive amaranthus production through irrigation [14]. Therefore, a simple random sample was employed to choose a total of 20 farmers, 20 transporters, 20 traders (open markets), 20 supermarket attendants and 20 consumers. Stakeholders in the amaranthus supply chain were identified and invited to a baraza. Amaranthus samples were also collected at each supply chain stage for further analysis.

Data Collection

Data for the study were collected through administration of a structured questionnaire. Pretesting was conducted and necessary adjustments were made to help convey appropriate data for the study. Focus group discussions were conducted in each sub-county involving farmers' organizations, local farmers, traders, retailers, transporters and consumers. The variables collected through the focus group discussions included causes of postharvest losses, possible solutions for postharvest losses, role of the government (County and National) in curbing or addressing postharvest losses, main challenges facing amaranthus along the supply chain, the technology used in postharvest handling and their challenges.

Variables collected through the questionnaire were socio-demographic profiles causes of postharvest losses along the supply chain node, means of transport, storage, and packaging. Three 50 kg bags of amaranthus were also sampled and weighed at each supply chain node to determine quantitative, economic and qualitative losses through a participatory approach. Temperature and relative humidity data were also recorded throughout the supply chain.

Quantitative loss was determined by measuring fresh weight at each supply chain node to determine fresh weight loss. Economic loss was determined based on fresh weight loss. Qualitative loss was determined by 5-point Likert scale based on degree of yellowing, wilting, presence of foreign bodies, mechanical damage and pest damage where 1 = 0-20%, 2= 21-40% 3=41-60%, 4=61-80% and 5=81-100%.

Data Analysis

Data collected from the three counties were pooled and examined for descriptive statistics. The means and percentages were used to describe results. Analysis was with the Statistical Package for Social Sciences (ver. 23, SPSS Inc., Chicago, IL).

Results

Socio-Demographic Profiles

In terms of age, majority of those interviewed were between 18 to 35 years (farmers, supermarket attendants) and between 36 to 55 years (transporters, open market attendants and consumers). Majority of the farmers, transporters and supermarket attendants were male while female was more for the case of open market traders and consumers). Married people were more in all the supply chain node except for supermarket attendants that had more that were single. Education level slightly increased with supply chain node. Majority of farmers and transporters were drop-outs, open market traders were mainly primary school leavers, open supermarket attendants were high school leavers and consumers were mainly college and degree holders. In all the studied supply chain node, main decision makers were husbands (Table 2).

|

|

|

Supply Chain Node |

||||

|

Variable |

Category |

Farmers |

Transporters |

Open Markets |

Supermarkets (Closed Markets) |

Consumers |

|

Age (years) |

18 to 35 |

40.1 |

6.6 |

37.6 |

57.4 |

13.6 |

|

36 to 55 |

37.5 |

55.9 |

38.7 |

36.9 |

46.4 |

|

|

>56 |

22.4 |

37.5 |

23.7 |

5.7 |

40.0 |

|

|

Gender |

Male |

55.9 |

78.5 |

36.2 |

53.6 |

45.3 |

|

Female |

44.1 |

21.5 |

63.8 |

46.4 |

54.7 |

|

|

Others |

0.0 |

0.0 |

0.0 |

0.0 |

0.0 |

|

|

Marital status |

Single |

12.7 |

10.6 |

14.2 |

44.2 |

5.2 |

|

Married |

65.6 |

57.3 |

64.3 |

30.4 |

45.6 |

|

|

Separated |

14.4 |

12.1 |

11.6 |

10.2 |

23.2 |

|

|

Divorced |

3.7 |

9.7 |

3.1 |

9.6 |

10.8 |

|

|

Widowed |

3.6 |

10.3 |

6.8 |

5.6 |

15.2 |

|

|

Education level |

Limited (drop-out) |

26.7 |

27.8 |

20.8 |

2.5 |

9.3 |

|

Primary |

23.4 |

21.2 |

24.6 |

5.4 |

13.5 |

|

|

Secondary |

23.1 |

25.7 |

22.7 |

54.6 |

16.9 |

|

|

College |

14.2 |

13.9 |

15.8 |

27.3 |

31.6 |

|

|

Graduate |

12.6 |

11.4 |

16.1 |

10.2 |

28.7 |

|

|

Occupation |

Government employment |

13.5 |

2.6 |

3.7 |

0.0 |

26.7 |

|

Own/family business |

17.8 |

22.6 |

20.2 |

25.6 |

24.6 |

|

|

Casual jobs |

25.7 |

20.5 |

22.1 |

22.3 |

10.2 |

|

|

Private sector employment |

11.2 |

17.1 |

11.4 |

0.0 |

22.9 |

|

|

None |

27.8 |

32.6 |

40.5 |

47.6 |

14.2 |

|

|

Others |

4.0 |

4.6 |

2.1 |

4.5 |

1.4 |

|

|

Key decision maker |

Husband |

47.9 |

39.8 |

49.6 |

35.2 |

40.6 |

|

Wife |

15.6 |

19.2 |

17.2 |

23.4 |

24.3 |

|

|

Son(s) |

13.1 |

14.3 |

16.8 |

18.3 |

17.2 |

|

|

Daughter(s) |

12.1 |

13.8 |

14.6 |

20.6 |

15.8 |

|

|

Others |

11.3 |

12.9 |

1.8 |

2.5 |

2.1 |

|

Table 2: Socio-demographic characteristics (%) of amaranthus supply chain actors in coastal Kenya (n = 60 for each supply chain node).

Causes of Postharvest Losses

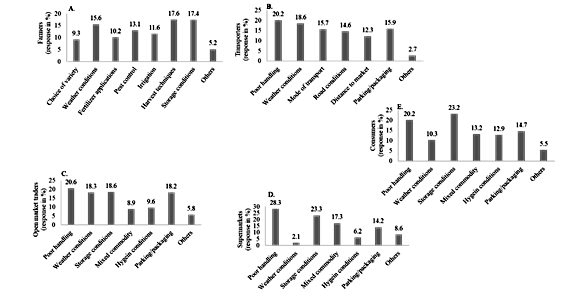

Major causes of postharvest losses of amaranthus reported by farmers were inappropriate harvest techniques (17.6%), and lack of proper storage conditions (17.4%) (Figure 2A). For transporters, majority reported improper handling of the produce (20.2%) and bad weather conditions (18.6%) as the major causes of amaranthus postharvest losses (Figure 2B). Similarly, in the open markets, major causes of postharvest losses were reported to be poor handling (20.6%), inappropriate storage conditions (18.6%), bad weather conditions (18.4%), and lack of appropriate packaging (18.2%) (Figure 2C). In the supermarkets, major postharvest losses were reported to be caused by inappropriate handling (28.3%), inappropriate storage conditions (23.3%), mixed commodity storage (17.3%), and lack of proper packaging materials (14.2%) (Figure 2D). Consumers reported that postharvest losses were mainly caused by improper storage conditions (23.2%), inappropriate handling (20.2%), and lack of proper packaging material (14.7%) (Figure 2E).

Figure 2: Causes of amaranthus postharvest losses along the supply chain (n=20 for each supply chain node).

Figure 2: Causes of amaranthus postharvest losses along the supply chain (n=20 for each supply chain node).

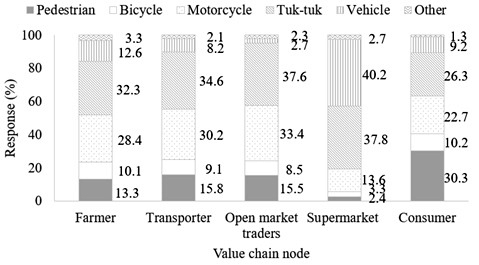

Means of Transport

The most common means of transport along the amaranthus supply chain was tuk-tuk (32.3 to 40.2%) or motorcycle (28.4 to 37.8%), except for consumers where majority (30.3%) preferred walking to purchase amaranthus (Figure 3).

Figure 3: Means of transporting amaranthus along the supply chain.

Figure 3: Means of transporting amaranthus along the supply chain.

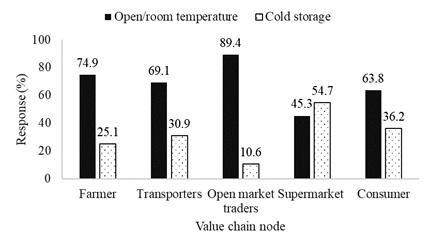

Storage

The most common type of storage of amaranthus was under room conditions or open air (63.8 to 89.4%), except for supermarkets amaranthus are kept under cold storage (54.7%) (Figure 4).

Figure 4: Method of storage of amaranthus along the supply chain.

Figure 4: Method of storage of amaranthus along the supply chain.

Packaging

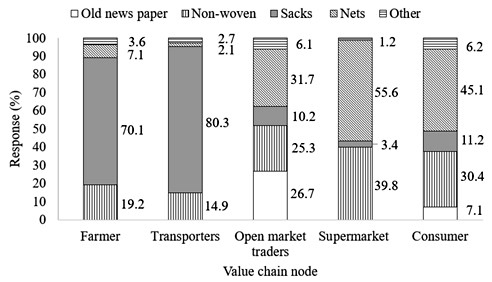

Responses of packaging varied with supply chain node (Figure 5). The most common packaging preferred by farmers (70.1%) and transporters (80.3%) was sacks, while open market traders (31.7%), supermarkets (55.6%) and consumers (45.1%) preferred nets for packaging amaranthus. However, some amaranthus supply chain actors especially in the open market (26.7%) were using old newspaper for wrapping amaranthus. Some amaranthus supply chain actors were secretly using the banned polyethylene bag for packaging amaranthus as reported by farmers (3.6%), transporters (2.7%), open market traders (6.1%), and consumers (6.2%) under others. Majority of the supply chain actors indicated that they were using the polythene bags for lack of a better packaging materials for amaranthus.

Figure 5: Types of packaging materials used in amaranthus supply chain.

Figure 5: Types of packaging materials used in amaranthus supply chain.

Qualitative Losses

Qualitative losses varied with supply chain node (Table 3). Yellowing was highest in the open-air markets (21 to 40%). Wilting was highest after transportation (41 to 60%), followed by at harvest (21 to 40%). Foreign bodies were highest at harvest (21 to 40%). Mechanical damage was highest at harvest and during transportation (21 to 40%). Pest damage did not vary along the supply chain. Generally, amaranthus at supermarkets and those purchased by consumers had the best quality compared with other supply chain nodes.

|

Parameters |

At Harvest (27.9°C, 79.2%)z |

After Transportation (29.2°C, 81.4%) |

In the Open Market |

At the Supermarkets (28.2°C, 77.6%) |

After Consumer Purchase (23.2°C, 84.6%) |

|

Yellowing |

*y |

* |

** |

* |

* |

|

Wilting |

** |

*** |

* |

* |

* |

|

Foreign bodies |

** |

* |

* |

* |

* |

|

Mechanical damage |

** |

** |

* |

* |

* |

|

Pest damage |

* |

* |

* |

* |

* |

Table 3: Qualitative losses of amaranthus along the supply chain.

Note: zTemperature and relative humidity conditions at each supply chain node

yRepresent levels of magnitude: *0-20%, **21-40%, ***41-60%, ****61-80%, *****81-100%

Quantitative and Economic Losses

The highest quantitative and economic loss was observed by consumers who purchased amaranthus from supermarkets (18.8%), followed by at harvest (17.6%), then consumers who purchased their amaranthus from open markets (15.1%), transportation (14.6%), then open market (10.6%) while supermarkets had the lowest postharvest loss of amaranthus (Table 4A). Cumulative quantitative and economic loss of amaranthus along the supply chain was highest when consumers bought amaranthus from the open market followed field to supermarket (closed market) pathway (57.9%) compared with when amaranthus followed field to open market pathway (52.7%) (Table 4B).

|

Supply Chain Nodez |

Fresh Weight (kg/bag)y |

Weight Loss (kg/bag) |

Weight Loss (%)x |

Economic Loss (Kes/bag)w |

Economic Loss (Kes/ha)v |

|

A. Loss Per Supply Chain Node |

|||||

|

After harvest (after sorting) |

29.4 |

6.3 |

17.6 |

220.50 |

222,500.00 |

|

After transportation |

24.2 |

5.2 |

14.6 |

182.00 |

182,000.00 |

|

In the open market |

20.4 |

3.8 |

10.6 |

133.00 |

133,000.00 |

|

At the supermarkets (closed market) |

23.6 |

0.6 |

1.7 |

21.00 |

21,000.00 |

|

Consumer (from open market) |

15.0 |

5.4 |

15.1 |

189.00 |

189,000.00 |

|

Consumer (from supermarket) |

16.9 |

6.7 |

18.8 |

234.50 |

234,500.00 |

|

B. Cumulative Loss Along the Supply Chain |

|||||

|

After harvest (after sorting) |

29.4 |

6.3 |

17.6 |

220.50 |

220,000.50 |

|

After transportation |

24.2 |

11.5 |

32.2 |

402.50 |

402,000.50 |

|

In the open market |

20.4 |

15.3 |

42.8 |

535.50 |

535,000.50 |

|

At the supermarkets (closed market) |

23.6 |

12.1 |

33.9 |

423.50 |

423,000.50 |

|

Consumer (from open market) |

15.0 |

20.7 |

57.9 |

724.50 |

724,500.00 |

|

Consumer (from supermarket) |

16.9 |

18.8 |

52.7 |

658.00 |

658,000.00 |

Table 4: Quantitative and economic losses of amaranthus along the supply chain.

Note: zTemperature and relative humidity conditions at each supply chain node was: At harvest (27.9°C, 79.2%), During transportation (29.2°C, 81.4%), In the open market (28.2°C, 77.6%), At the supermarkets (23.2°C, 84.6%). Supply chain node were 2 options: Option 1=Harvest → Transportation → open market → consumer; Option 2=Harvest → Transportation → supermarket → consumer

yFresh Weight at Harvest=35.7kgs in a 50kg bag (before sorting).

wEconomic loss (Kes/bag) = Weight loss (kg/bag) × Price per kg (Kes)

wEconomic loss (Kes/bag) = Weight loss (kg/bag) × Price per kg (Kes)

vEconomic loss (Kes/ha) = Weight loss (bags/ha) × Price per kg (Kes)

Price=Kes 35/kg

Amaranthus leaf yield/season in coastal Kenya = 50 t/ha = 50,000 kgs = 1,000 bags

Kes 140 €1 = $ 1.07

Discussion

In the study farmers and supermarket attendants were more youthful (18 to 35 years) while other supply chain actors were older (36 to 55 years). This could imply that amaranthus supply chain actors is being done by an economically active and productive population. This study agrees with the study by Gogo et al. [15], who observed that indigenous vegetable farmers is mainly dominated by young adults. Majority of amaranthus supply chain actors were male except for supermarkets that were dominated by female. The increase in amaranthus as a commercial venture may have attracted more men into it especially as majority are heads of the household, being decision makers and responsible for providing for the family. This is also corroborated by the results of this study where more married people dominated amaranthus supply chain except supermarkets. Supermarkets tend to employ more female as a marketing strategy. Education level slightly increased with supply chain node. Due to increased awareness of health-related importance of amaranthus more educated consumers have increasingly become cautious of lifestyle diseases and therefore consuming more indigenous vegetables including amaranthus. Majority of amaranthus supply chain actors were either casual workers or were self-employed. This could be attributed to the supply chain actors being middle income earners and therefore venturing into amaranthus supply chain to supplement their income to meet their daily needs.

Postharvest loss refers to the degradation in quality and quantity of food production from harvest to consumption [16]. In the current study, farmers reported that the major causes of amaranthus losses were inappropriate harvest techniques and lack of proper storage conditions. This could be attributed to the majority of the respondents' lack of knowledge on how to harvest and store amaranthus to minimise the postharvest. The findings are similar to Gogo et al. [13], who reported that most farmers do not understand the use of cold storage for specific for in handling leafy vegetables. According to Elik et al. [17], poor harvesting techniques can lead to irreparable damage to horticultural produce. Use of harvest tools such as knives should be kept clean to minimise contamination and sharp to minimise damage to the vegetables hence reducing postharvest losses. Patel et al. [18], reported that most farmers in developing countries cannot afford refrigeration and cold storage facilities to store their horticultural produce. Despite the majority of the farmers acknowledging that major postharvest losses are due to bad weather they could not afford the storage facilities due lack of capital to buy the storage facilities. The majority of transporters reported improper handling of the produce and bad weather conditions as the major causes of amaranthus postharvest losses. This could be attributed to bruises during loading and off-loading and through transpiration. According to Kiaya [19], to minimise losses during transport requires distinctive attention to vehicles, infrastructure, equipment and handling. Watering fresh produce causes decay, rotting, and extensive postharvest losses hence should not be watered before loading. The majority of the transporters were using tuk tuk and motorcycles which are not for transporting fresh horticultural produce hence exposing amaranthus to moisture loss through transpiration. Al-Dairi et al. [20], carried out research on mechanical damage to fresh produce in postharvest transportation and reported that vibrations during transit as one of the major quality challenges causing mechanical damage to fresh produce. Respondents in the open markets and consumers reported that the major causes of postharvest losses were reported to be poor handling, inappropriate storage conditions, bad weather conditions and lack of appropriate packaging. This could be attributed to poor handling conditions in the market. The amaranthus in the open market were sold in tied bundles and not packaged hence exposed to higher humidity and temperatures. Coastal counties are characterised by higher surrounding air temperature and humidity which promote disintegration of chlorophyll leading to premature yellowing, dehydration, wilting and fast softening [21]. The unpackaged vegetable in the market exposes the amaranthus to moisture loss, mechanical damage and microorganisms that can cause spoilage, leading to a decrease in quality and shelf life. In the supermarkets, major postharvest losses were reported to be caused by inappropriate handling, inappropriate storage conditions and mixed commodity storage. This could be attributed to a lack of knowledge on the appropriate handling of amaranthus, and appropriate storage temperatures [13]. According to Mariah et al. [22], some vegetables and fruits produce ethylene gas as they ripen, which can accelerate the ripening and spoilage of neighboring produce and suggest that packaging can help mitigate this by creating a barrier between different types of vegetables.

The current study shows the most common means of transport along the amaranthus supply chain was tuk tuk or motorcycle except for consumers where the majority preferred walking to purchase. This could be due to poor road networks in the rural areas in the farms where farmers grow amaranthus and they are the most accessible and less expensive means of transport. Bishop et al. [23], reported that motorcycle taxis are increasingly acting as feeder services in rural areas, linking off-road villages and are more affordable means of motorised transport services.

The current study shows that the most common type of storage of amaranthus was under room conditions or open air (63.8 to 89.4%), except for supermarkets where amaranthus are kept under cold storage. This could be attributed to the high cost of installation of the storage facilities and the cost of electricity [13]. The majority of the respondents were aware of the effect of the weather conditions on the postharvest losses yet they were not applying the technology.

Packaging is indispensable in vegetable protection, temperature control and reducing damage during transport and handling [17]. The results from the current study show that the most common packaging preferred by farmers and transporters was sacks, while open market traders, supermarkets and consumers preferred nets for packaging amaranthus. This could be attributed to the supply chain actors reducing costs by using locally available materials which are accessible and cheaper to reduce costs. Similar findings were reported by Apolot et al. [24], who reported the use of cheaper available packing materials including sacks, bamboo baskets, boxes and wooden crates at on-farm packing to ease handling during transportation to the market. According to Tapsoba et al. [25], farmers prefer using packaging materials made from agricultural waste and by-products to those made from synthetic materials since the materials are cheaper, using the traditional packaging materials promotes local expertise. In February 2017 the Kenyan Government gazetted a ban on the use of single-use polythene bags, a few retailers are still using it to package fresh horticultural produce and other products in the market [26]. According to Feizi et al. [27], use of thin polythene packaging bags negatively affects the postharvest quality of vegetables.

Yellowing is one of the essential symptoms of quality degradation in fresh vegetables [28]. Yellowing was highest in the open-air markets while wilting was highest after transportation followed by at harvest. Yellowing could be attributed to exposure of the tied and unpackaged bundle of amaranthus to the ambient temperature and lack of cold storage systems in the market which enhance degradation. According to Dusenge et al. [29], higher ambient temperatures usually accelerate leaf metabolisms hence causing increased degradation of the chlorophyll leading to yellowing. In the market, retailers put amaranthus adjacent to other fruits which produce ethylene hormone which enhances chlorophyll degradation [30]. Foreign bodies were highest at harvest while mechanical damage was highest both at harvest and during transportation. This could be attributed to contamination at the farm level during harvesting collection and packaging. During transportation of the amaranthus, the Tuk-Tuk which is the commonly used means of transport may not be adequately cleaned and are not covered hence exposing the vegetables to surface contamination including dust [31]. Similarly, Al-Dairi et al. [20], reported that vibration generated during transportation causes mechanical damages to the vegetables. At the supermarkets, the vegetables were kept in cold storage which preserve their quality [32].

From the current study, the highest quantitative and economic loss was observed by consumers who purchased amaranthus from supermarkets which could be attributed to poor handling conditions and wastage during preparation of the vegetables for consumption. The number of consumers buying amaranthus was also relatively few hence end up staying on the shelves for longer days. Cumulative quantitative and economic loss of amaranthus along the supply chain was highest when consumers bought amaranthus from the open market. Escobar-López et al. [33], reported that most consumers perceived supermarkets as the market for the rich consumers. Similarly, Križan et al. [34], reported the decision on where to purchase depends on factors like accessibility, price, quality, distance and terms of payment. Supermarkets had the lowest postharvest loss of amaranthus. This could be attributed to amaranthus kept in cold storage of amaranthus on the shelves hence longer shelf life [35].

Conclusion and Recommendation

The study examined postharvest losses in the amaranthus supply chain involving farmers, transporters, market traders, supermarket attendants, and consumers. From the study, causes of postharvest losses varied with supply chain. Major causes of postharvest losses reported were inappropriate harvest techniques, lack of proper storage conditions, improper handling of the produce, bad weather conditions, inappropriate storage conditions, lack of appropriate packaging, and mixed commodity storage. The most common means of transporting amaranthus was by use of tuk-tuk (32.3 to 40.2%) or motorcycle (28.4 to 37.8%). The most common type of storage of amaranthus was under room conditions or open air (63.8 to 89.4%). The most common packaging used was sacks and nets. However, old newspaper were being used in the open markets. Polyethylene bags that have been banned in Kenya were secretly being used. Major qualitative losses of amaranthus observed were yellowing which was highest in the open-air markets (21 to 40%). Wilting was highest after transportation (41 to 60%). Foreign bodies were highest at harvest (21 to 40%). Mechanical damage was highest at harvest and during transportation (21 to 40%). Pest damage did not vary along the supply chain. The highest quantitative and economic loss was between 52.7 to 57.9% depending on the amaranthus supply chain. Improving harvesting techniques and handling practices, enhancing storage conditions, and promoting proper packaging methods tailored to each node of the chain. Additionally, investing in transportation infrastructure and cold storage systems can help minimize postharvest loss.

Acknowledgement

We are grateful to the Pwani University for providing experimental sites during the experiment. The work forms part of the requirements for the doctor of philosophy degree of Pwani University.

References

- Muriuki EN, Sila DN, Onyango A (2014) Nutritional diversity of leafy amaranth species grown in Kenya. Journal of Applied Biosciences 79: 6818-6825.

- Pulvento C, Sellami MH, Lavini A (2022) Yield and quality of Amaranthus hypochondriacus grain amaranth under drought and salinity at various phenological stages in southern Italy. J Sci Food Agric102: 5022-5033.

- Kimiywe J, Waudo J, Mbithe D, Maundu P (2007) Utilization and medicinal value of indigenous leafy vegetables consumed in urban and peri-urban Nairobi. African Journal of Food, Agriculture, Nutrition and Development 7: 1-15.

- Achigan-Dako EG, Sogbohossou OE, Maundu P (2014) Current knowledge on Amaranthus spp.: Research avenues for improved nutritional value and yield in leafy amaranths in sub-Saharan Africa. Euphytica 197: 303-317.

- Jiménez-Aguilar DM, Grusak MA (2017) Minerals, vitamin C, phenolics, flavonoids and antioxidant activity of Amaranthus leafy vegetables. Journal of Food Composition and Analysis58: 33-39.

- Ndalilo L, Wekesa C, Mbuvi MT (2020) Indigenous and local knowledge practices and innovations for enhancing food security under climate change: Examples from Mijikenda communities in coastal Kenya. Sustainability Challenges in Sub-Saharan Africa II: Insights from Eastern and Southern Africa. Pg No: 63-82.

- Oluoch OB, Muindi EM, Gogo EO (2021) Saline irrigation water retards growth of amaranthus in coastal Kenya. NASS Journal of Agricultural Sciences3: 43-50.

- Gogo EO, Förster N, Dannehl D, Frommherz L, Trierweiler B, et al. (2018) Postharvest UV-C application to improve health promoting secondary plant compound pattern in vegetable amaranth. Innovative Food Science and Emerging Technologies 45: 426-437.

- Adewoyin OB (2023) Pre-harvest and postharvest factors affecting quality and shelf life of harvested produce. New Advances in Postharvest Technology.

- Murigi WW (2016) Management of ware potato sprouting during long term storage in the tropical conditions of Kenya, Doctoral dissertation, University of Nairobi, Kenya.

- Iordachescu G, Ploscutanu G, Pricop EM, Baston O, Barna O (2019) Postharvest losses in transportation and storage for fresh fruits and vegetables sector. Journal of International Scientific Publications7: 244-251.

- Umeohia UE, Olapade AA (2024) Physiological processes affecting postharvest quality of fresh fruits and vegetables. Asian Food Science Journal23: 1-14.

- Gogo EO, Opiyo AM, Christian U, Huyskens-Keil S (2016) Postharvest treatments of African leafy vegetables for food security in Kenya: A review. African Journal of Horticultural Science 9: 32-39.

- Redondo PVT (2016) Purposive sampling in the analysis of count data. The Philippine Statistician 65: 41-52.

- Gogo EO, Opiyo AM, Hassenberg K, Ulrichs C, Huyskens-Keil S (2017) Postharvest UV-C treatment for extending shelf life and improving nutritional quality of African indigenous leafy vegetables. Postharvest Biology and Technology129: 107-117.

- Kasso M, Bekele A (2018) Post-harvest loss and quality deterioration of horticultural crops in Dire Dawa Region, Ethiopia. Journal of the Saudi Society of Agricultural Sciences17: 88-96.

- Elik A, Yanik DK, Istanbullu Y, Guzelsoy NA, Yavuz A, et al. (2019) Strategies to reduce post-harvest losses for fruits and vegetables. International Journal of Scientific and Technological Research5: 29-39.

- Patel DP, Jain SK, Lakhawat SS, Wadhawan N (2022) A low-cost storage for horticulture commodities for enhancing farmer's income: An overview on evaporative cooling. Journal of Food Process Engineering45:

- Kiaya V (2014) Post-harvest losses and strategies to reduce them. Technical Paper on Postharvest Losses, Action Contre la Faim (ACF)25: 1-25.

- Al-Dairi M, Pathare PB, Al-Yahyai R, Opara UL (2022) Mechanical damage of fresh produce in postharvest transportation: Current status and future prospects. Trends in Food Science & Technology, 124, 195-207.

- El-Ramady HR, Domokos-Szabolcsy É, Abdalla NA, Taha HS, Fári M (2015) Postharvest management of fruits and vegetables storage. Sustainable Agriculture Reviews 15: 65-152.

- Mariah MAA, Vonnie JM, Erna KH, Nur’Aqilah NM, Huda N, et al. (2022) The emergence and impact of ethylene scavengers’ techniques in delaying the ripening of fruits and vegetables. Membranes12:

- Bishop T, Barber C, Charman S, Porter G, Bradbury A (2018) Enhancing understanding on safe motorcycle and three-wheeler use for rural transport. Amend and Transaid. ReCAP project RAF2114A.

- Apolot MG, Acham H, Ssozi J, Namutebi A, Masanza M, et al. (2020) Postharvest practices along supply chains of Solanum aethiopicum (shum) and Amaranthus lividus (linn) leafy vegetables in Wakiso and Kampala Districts, Uganda. African Journal of Food, Agriculture, Nutrition and Development20: 15978-15991.

- Tapsoba LD, Kiemde SM, Lamond BF, Lépine J (2022) On the potential of packaging for reducing fruit and vegetable losses in Sub-Saharan Africa. Foods11:

- Omondi IO, Asari M (2019) Impact of plastic bag ban on behavior and attitudes in Kenya. In Proceedings of the Annual Conference of Japan Society of Material Cycles and Waste Management the 30th Annual Conference of Japan Society of Material Cycles and Waste Management. Japan Society of Material Cycles and Waste Management.

- Feizi S, Nasiri M, Bahadori H, Amiri MH (2020) The relationship between spiritual well-being and happiness among healthcare students: Application of the spiritual health questionnaire for the Iranian population.

- Luo X, Tong S, Fang Z, Qu Z (2019) Frontiers: Machines vs. Humans: The impact of artificial intelligence chatbot disclosure on customer purchases. Marketing Science.

- Dusenge ME, Duarte AG, Way DA (2019) Plant carbon metabolism and climate change: elevated CO2 and temperature impacts on photosynthesis, photorespiration and respiration. New Phytologist221: 32-49.

- Wei Y, Jin J, Xu Y, Liu W, Yang G, et al. (2021) Ethylene-activated MdPUB24 mediates ubiquitination of MdBEL7 to promote chlorophyll degradation in apple fruit. The Plant Journal108: 169-182.

- Gogo EO, Opiyo A, Ulrichs C, Huyskens-Keil S (2018) Loss of African indigenous leafy vegetables along the supply chain. International Journal of Vegetable Science24: 361-382.

- Ambuko J, Wanjiru F, Chemining’wa GN, Owino WO, Mwachoni E (2017) Preservation of postharvest quality of leafy amaranth (Amaranthus spp.) vegetables using evaporative cooling. Journal of Food Quality2017: 1-6.

- Escobar-López SY, Espinoza-Ortega A, Moctezuma-Pérez S, Chávez-Mejía C, Martínez-García CG (2022) Consumers’ perception of different types of food markets in Mexico. International Journal of Consumer Studies46: 147-160.

- Križan F, Bilková K, Novotná M, Kunc J, Hencelová P (2023) Consumer perception of food value: A comparative study of global supermarkets and local farmers' markets in Slovakia. Moravian Geographical Reports31: 184-193.

- Yahia EM, Fonseca JM, Kitinoja L (2019) Postharvest losses and waste. Postharvest Technology of Perishable Horticultural Commodities 43-69.

Citation: Oluoch OB, Muti S, Mulinge J, Gogo EO (2024) Causes and Levels of Postharvest Losses along Amaranthus Supply Chain. J Food Sci Nutr 10: 187.

Copyright: © 2024 Oluoch OB, et al. This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.